DIAMOND MOLD

Engineering Your Vision, Molding Excellence

Precision Injection Molding & Mold Manufacturing – Quality, Speed, Innovation

High Precision

Technical Support

Cost-effective

Rapid Response

About Us

Precision Molds, Perfect Parts

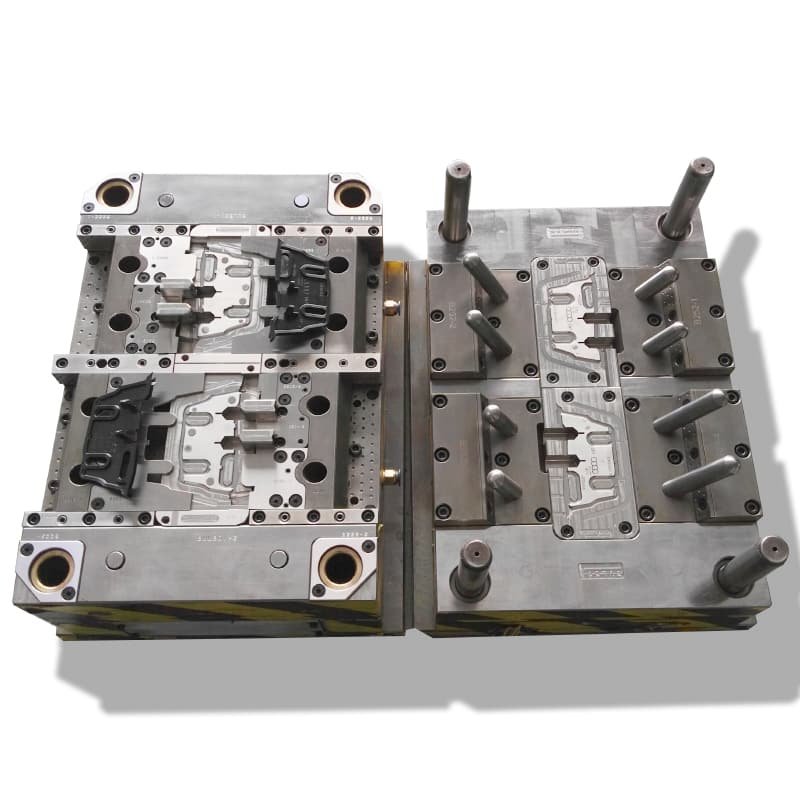

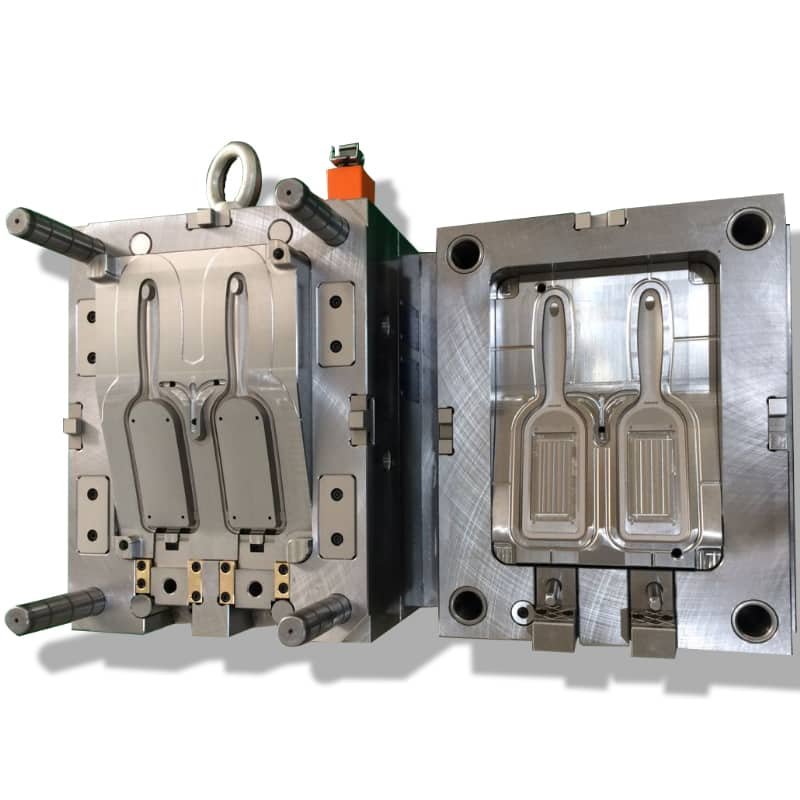

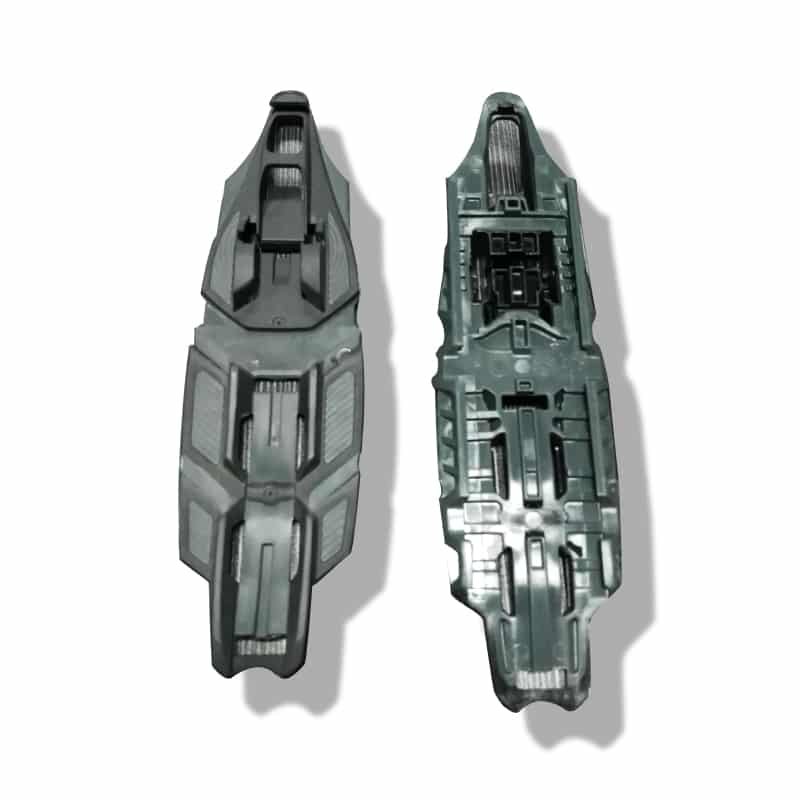

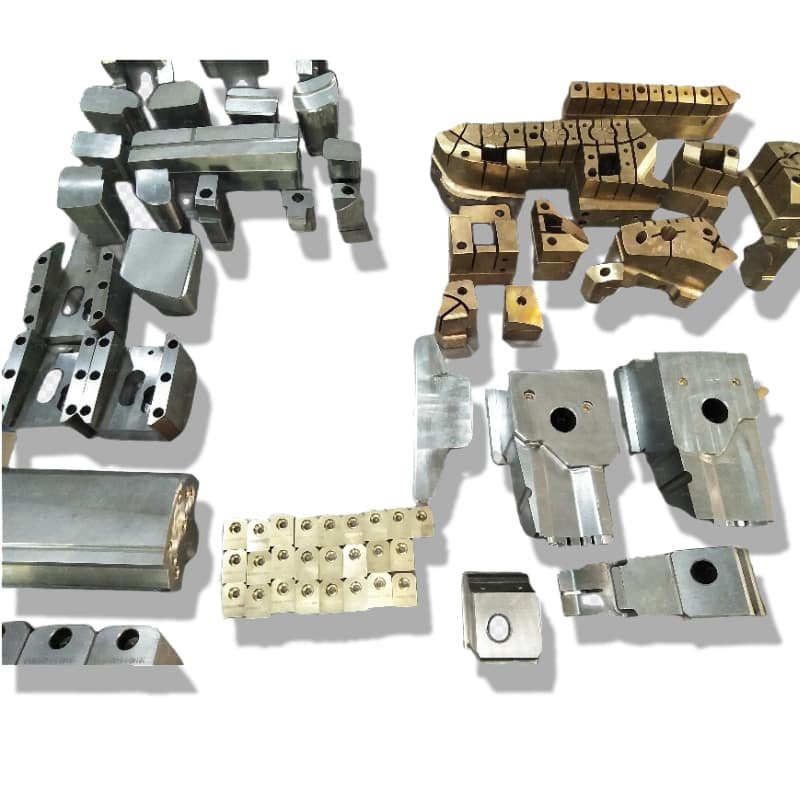

Shenzhen Diamond Mold Co., Ltd. was established in 2005. Since then we been primarily dedicated to the research, development, and manufacturing of automotive molds, furniture molds, digital product molds, plastic molds, two-color molds, and zinc-aluminum alloy molds.

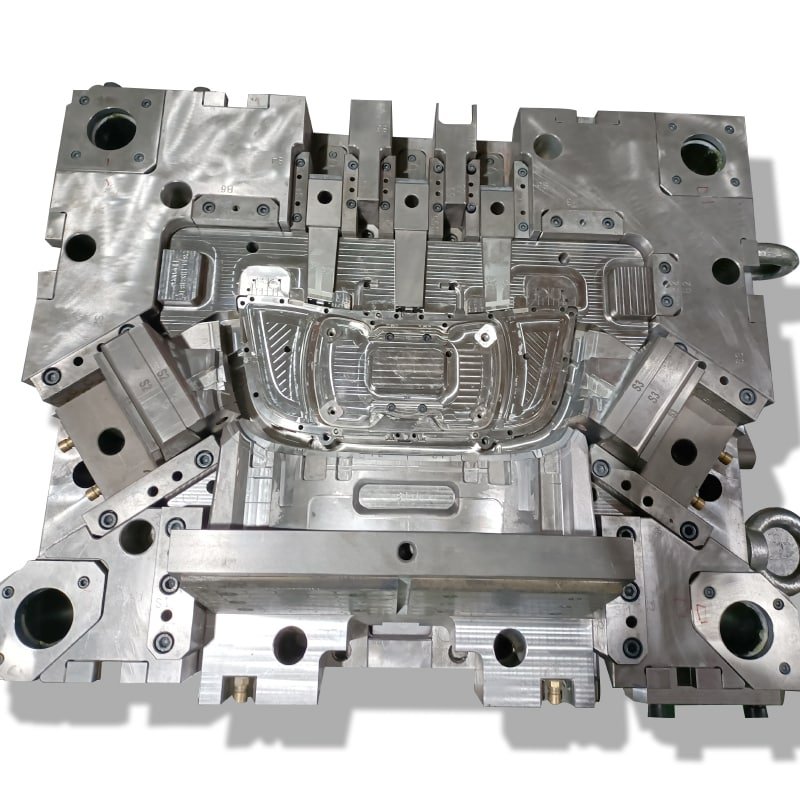

Automotive Molds

Electronics Molds

Appliance Molds

Medical Molds

Our professional design team tailors solutions to clients in different regions by utilizing appropriate mold standards such as HASCO, DME, and MISUMI to meet customer requirements.

- Global Standards

- Fast Service

- Affordable Pricing

- Verified Quality

- Customer Focused

- One-stop Solution

Our services

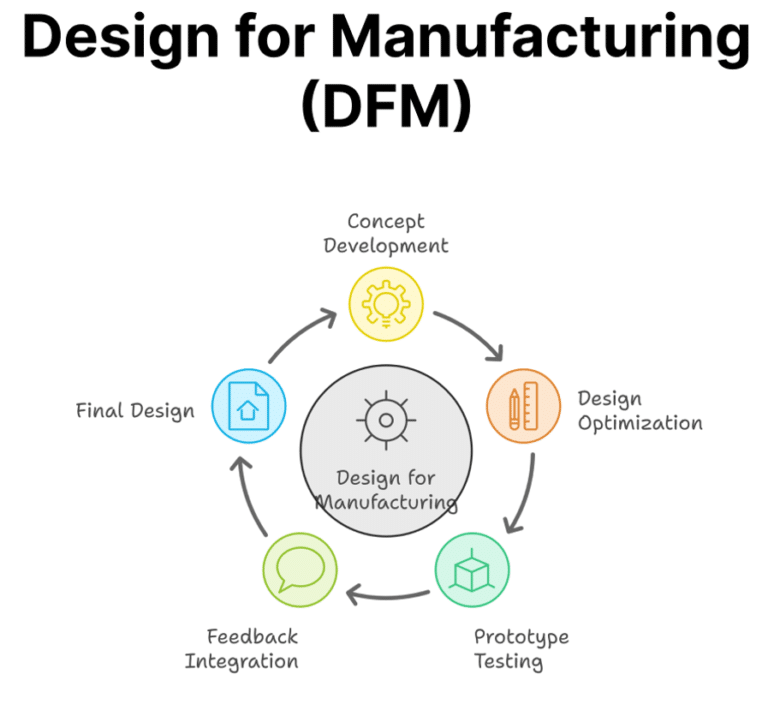

One-Stop Solution

From DFM to Mass Production. We Ensure Quality, Transparency, and On-Time Delivery for Global Clients.

DFM Analysis

Our engineers examine your 3D layout to optimize it for production and cost-saving.

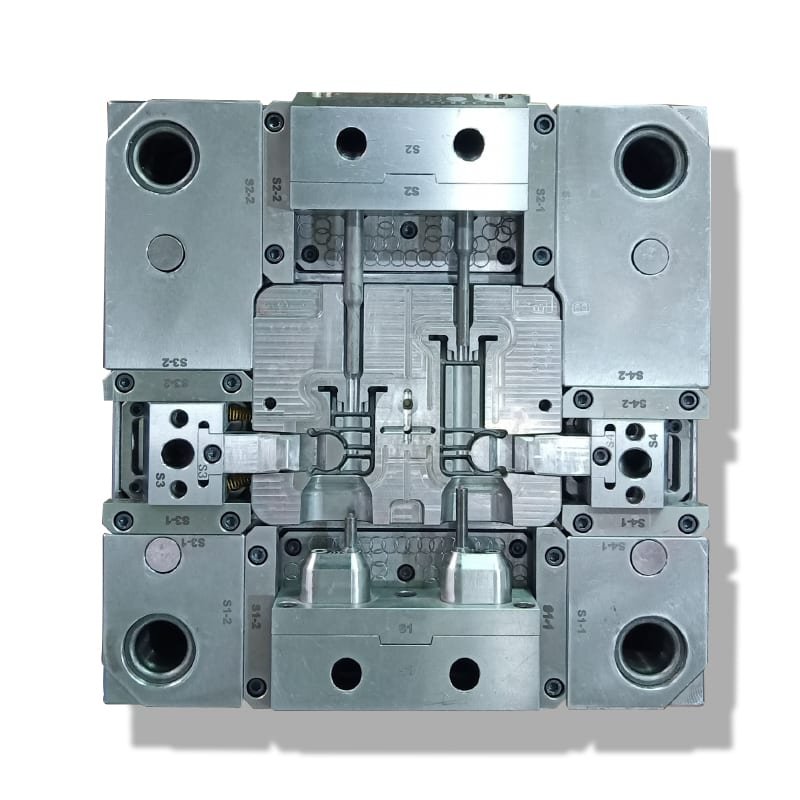

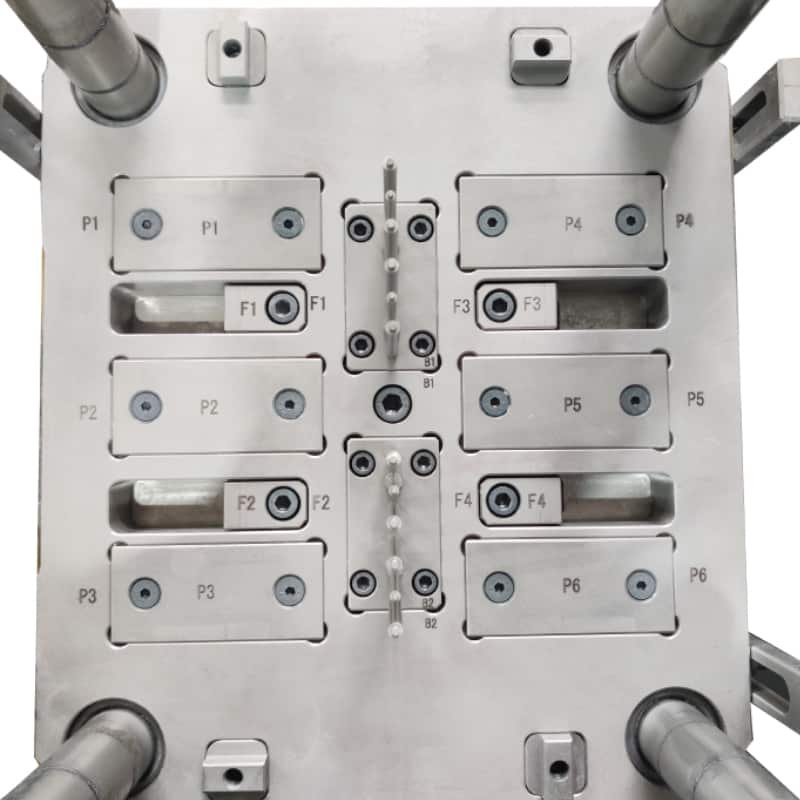

Mold Design

We engineer the mould’s entire shape and structures for precision, efficiency, and lifespan.

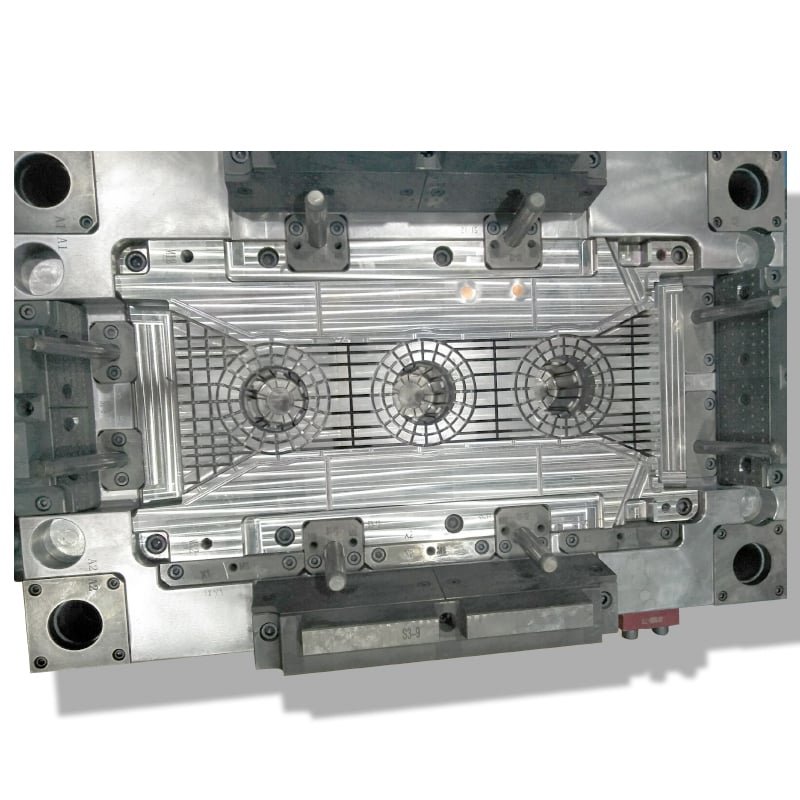

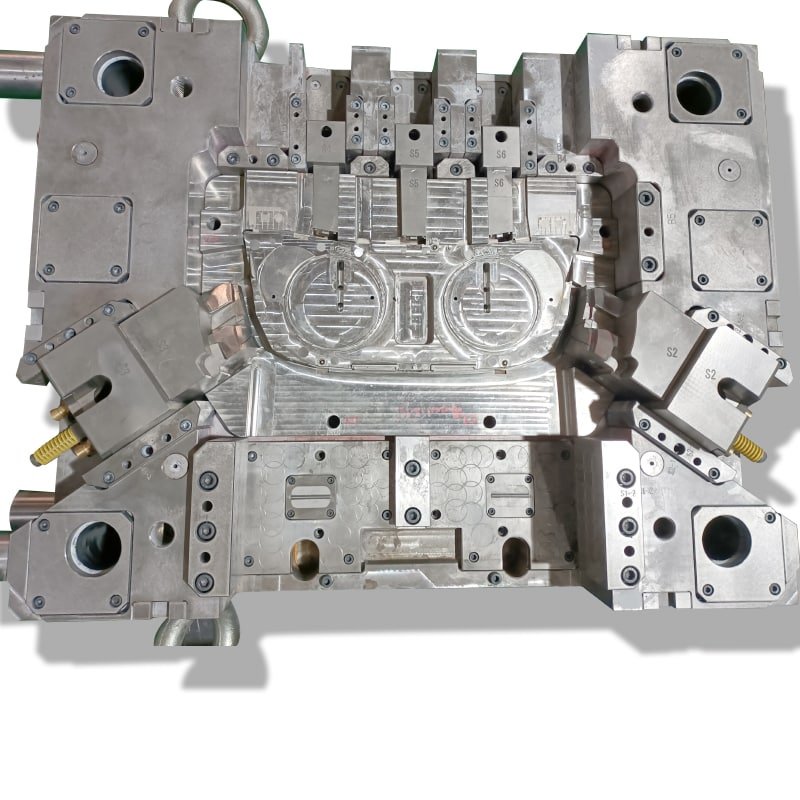

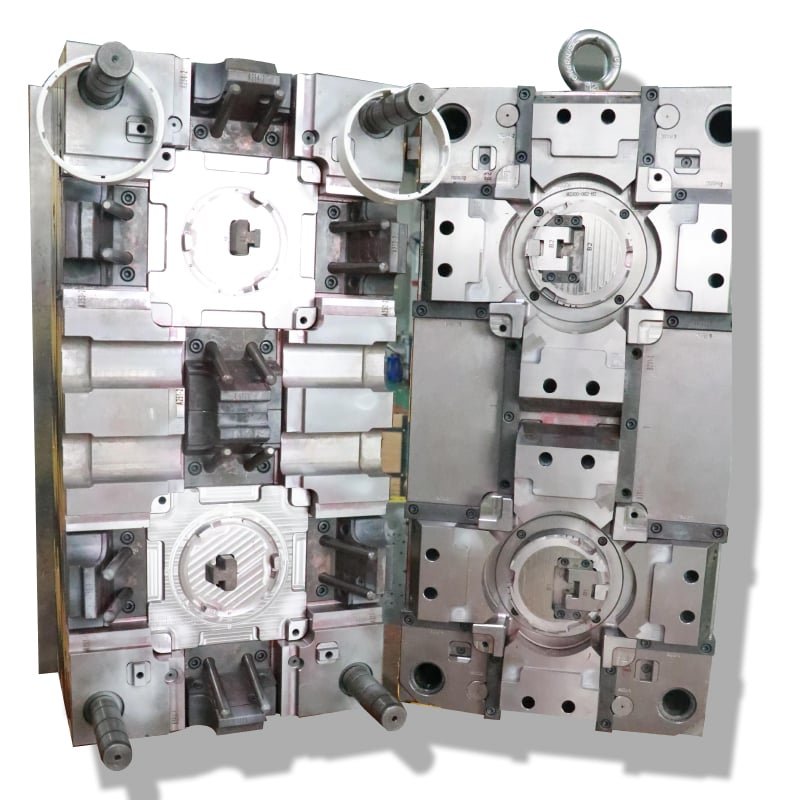

Mold Manufacturing

We make and assemble your mold with advanced equipment and strict quality control.

Mold Trial

We check, regulate, and validate the mould to guarantee the mold meet all specs.

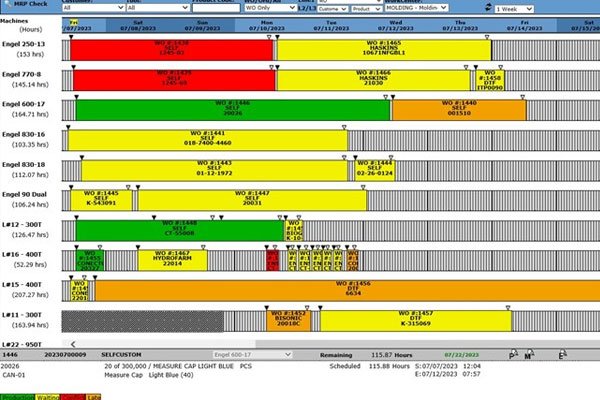

Injection Molding

We can produce accurate, consistent plastic parts at scale with our advanced injection molding machines.

Product Assembly

We assemble, finish, and pack your components into complete, ready-to-use products.

Our Process

Quality and reliability

Our engineering and inspection strictly follow ASME Y14.5 (GD&T) or ISO GPS standards.

Our Works

International Standards Compliance

Our engineering and inspection strictly follow ASME Y14.5 (GD&T) or ISO GPS standards.

From Design to Production – Bring Your Product to Life with Our Custom Mold Solutions

Precision, quality, and reliability define our mold manufacturing services. From custom designs to high-precision production, our experienced team and advanced equipment ensure that our molds and parts meet the highest standards and boost your manufacturing efficiency.

Request a Quote NowContact Us Today

info@diamondmold.com

Testimonials

Happy customers

Our customers are at the heart of everything we do. Over the years, we’ve built lasting relationships by delivering reliable repairs, honest advice, and exceptional service.

“Working with Diamond Mold has significantly improved our output. Their engineers understand complex automotive structures and consistently deliver molds with outstanding precision.”

Michael

Automotive Parts Supplier

“Diamond Mold’s technical guidance during the design stage saved us both time and cost. Truly a reliable partner for long-term tooling projects.”

David

Consumer Electronics Company

“Diamond Mold’s fast service and professional craftsmanship exceeded our expectations. From mold design to mass production, every step was handled carefully.”

Robert

Home Appliance Brand

Blog

Latest news

Stay informed with the latest insights, updates, and stories from our mold workshop. Explore our news to learn more about mold design, manufacturing tips, and the latest developments at our facility and industry.