Engineering Excellence in Every Mold Design

A reliable plastic mold design is mainly reflected in the quality of the molded plastic products (appearance quality and dimensional stability), the convenience, speed and simplicity of processing and manufacturing, the saving of money and manpower, the room for correction and improvement, the safety and stability during use, the ease of maintenance, the short molding cycle and long service life during injection molding, and the reasonable mold manufacturing.

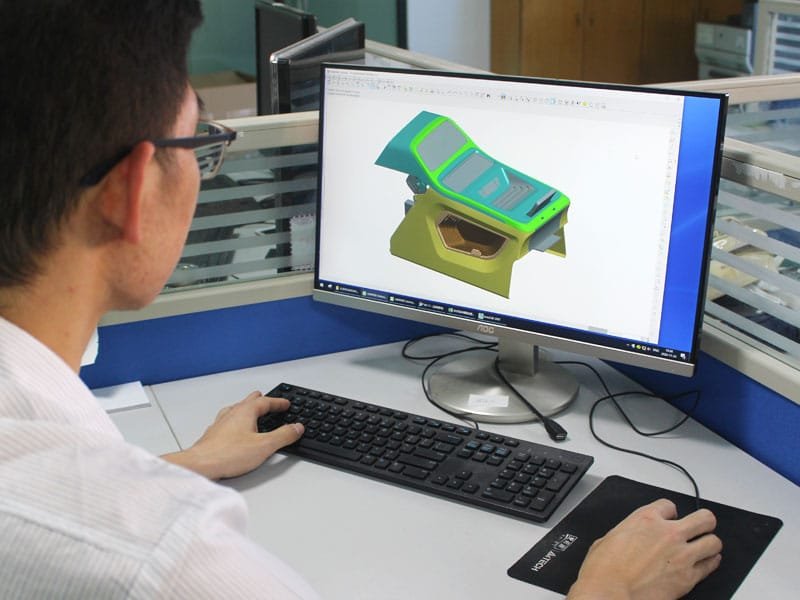

Our design team not only excels in technical expertise but also offers responsive and thoughtful support, working closely with clients to ensure every mold design fully meets project requirements.

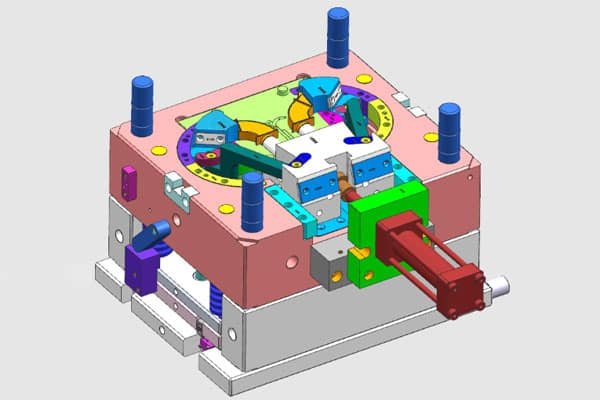

- Hot runner/cold runner systems

- Multi-cavity, family mold design

- Unscrewing, lifter, slide mechanisms

- Gas-assisted, insert molding design

- Existing Mold Redesign & Optimization

- Reverse Engineering & 3D Scanning

Main process of our mold design

Customer provides product drawing → Product analysis → Confirm plastic type → Confirm mold material → Convert to engineering drawing → Mirror image based on shrinkage → Improve assembly drawing → Order mold blank → Order mold core material → Drafting → 3D mold parting → Determine runner/gate method → Perform structural design based on layout drawing → Remove inserts → Correct 3D → Output engineering drawings (mold core/inserts/mold blank/disassembled parts) → Create BOM → Proofread and approve.

Mold design basis

The primary basis for our design is the product drawings and samples provided by the client. Our Designers will thoroughly analyze and understand the products and samples, and during the design process, we will verify each item one by one.

1, Dimensional accuracy and related dimensional correctness

1) For plastic products with high appearance requirements and low dimensional accuracy requirements, such as toys, the specific dimensions, except for those of the transfer assembly, only need to match well.

2) Products with very strict requirements for appearance and dimensions.

Is the draft angle reasonable?

Product wall thickness and uniformity.

Types of plastics. (Selection of mold steel and determination of shrinkage rate)

Surface requirements.

Product color.

Generally, color has no direct impact on mold design. However, when the product has thick walls and a large shape, uneven coloring is more likely to occur; and the darker the color, the more obvious the defects in the product will be.

2, Is there any post-processing after the product is molded?

If there are products with surface electroplating and the mold has multiple cavities, it is necessary to consider setting up auxiliary runners to connect the products together, and then separate them after the electroplating process is completed.

3, Batch size of products

The batch size of the products is an important basis for mold design. Customers must provide a range to determine the number of mold cavities, their size, mold materials, and lifespan.

4, Injection Molding Machine Specifications

5, Other requirements from customers

Our Designers will carefully consider and verify to ensure compliance with your requirements.

Several aspects to consider in the design

1) When we begin mold design, we should consider several options, weigh the advantages and disadvantages of each, and select the best one. We should also take T-die design seriously. Because of time constraints, designs that seem reasonable at the time may need improvement after practical production use.

2) After submitting the design proposal, it is essential to communicate frequently with the factory to understand the processing procedures and the conditions during manufacturing and use. Each mold should have a fixed process of analysis and summarizing gains and losses in order to continuously improve the mold design level.

3) When designing, refer to similar drawings from the past and learn from their experience and lessons.

4) The mold design department should be a whole, and each design member should not work independently. In particular, the conclusions of the mold design summary should have a unique style.

From the initial mold design to successful mold manufacturing and inspection, all technical documents generated during this period, such as task sheets, part drawings, technical specifications, mold assembly drawings, mold component drawings, base drawings, mold design specifications, inspection records, and mold trial and repair records, should be systematically organized, bound, numbered, and archived according to regulations. This may seem tedious, but it is extremely useful for future mold repairs and new mold design.

So after the mold design is completed, we will organize all the documents and send you the full set of design drawings and documentation.

Quality Assurance in Design

Design Review Protocols: 4-stage review process

Simulation Validation: Mold flow, cooling, structural analysis

Tolerance Management: GD&T standards application

Documentation Control: Revision history, change management

Compliance: Meeting international safety/quality standards

- DIN/ISO mold base standards

- SPI (Society of Plastic Industry) classifications

- Customer-specific standards accommodation

- Imperial/Metric system design

FAQ

The Most Frequently Asked Questions

If you have any questions about our mold design service, please feel free to contact us. Our design team is ready to help you.

What file formats do you accept for design input?

We accept most common formats, including STEP, IGES, XT, STL, DWG, and PDF.

How do you handle design changes during the process?

All changes are confirmed with you in advance, documented clearly, and updated in both the 2D and 3D files before final delivery.

What is your typical design lead time?

Usually 3–7 days, depending on the complexity of the part and mold structure.

Do you provide mold flow analysis reports?

Yes, we can provide mold flow analysis reports upon request.

How do you calculate the design cost? Based on mold price or complexity?

Our design cost is mainly based on part complexity, mold structure, and required delivery time.

Can you provide design-only services if I only need mold design?

Yes, we offer standalone mold design services without mold manufacturing.