What exactly is DFM?

DFM, or Design for Manufacturability, requires that the feasibility of manufacturing and ease of assembly of a product be considered from the initial design stage. Its core value lies in: by analyzing design information, assessing the feasibility of mold development and injection molding, and proposing practical improvement suggestions, thereby reducing subsequent production costs and risks.

General process of DFM for plastic parts at Diamond Mold

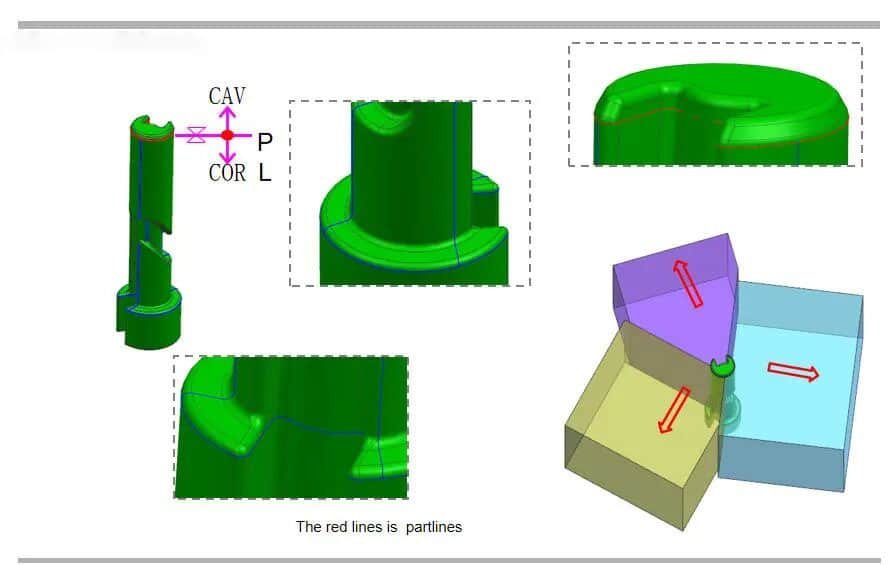

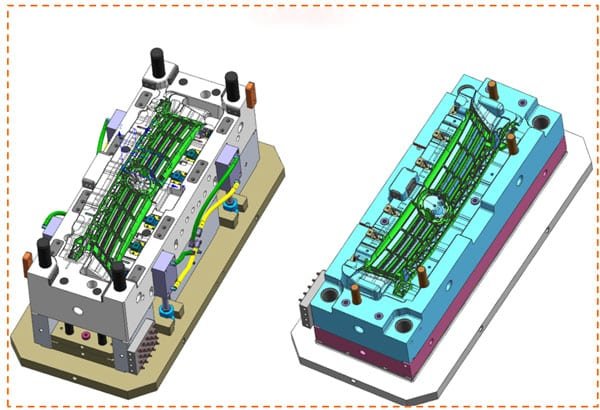

- Design completed → Before mold development: At this stage, the mold factory will issue a DFM report, which includes key points such as mold steel selection, injection material, gate location, wall thickness distribution, and parting line layout.

- Report feedback: Our product development engineers will continuously adjust the structure and optimize costs and production efficiency according to report feedback.

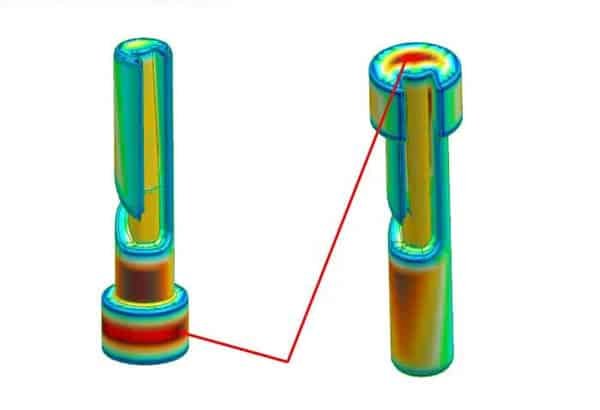

- Mold Flow Analysis (Optional): We will Simultaneously perform mold flow simulation to predict the optimal gate point, shrinkage marks, weld lines, and cavitation locations, providing data support for the final design.

⚡️According to industry statistics, more than 98% of plastic product development uses the aforementioned traditional DFM process.

DFM Analysis: Optimize Your Design for Manufacturing & Cost

Our expert DFM analysis identifies potential manufacturing issues before tooling begins, saving you time, reducing cost, and ensuring your part is designed for flawless production in our high-precision molds.

Avoid Costly Mistakes Before Your Mold is Made

DFM (Design for Product) is not about “finding faults,” but about ” turning good design into good products .” It embodies a design responsibility, a mindset where designers are responsible for whether a product can be built. This is the true meaning of “engineering thinking.”

As a proverb says:

“You can’t inspect quality into a product, you must design it in.”

You can’t add quality to a product through inspection; you have to design it in during the design process.

DFM is one of the key paths to realizing this concept.

- Reduce defect rate

- Shorten development cycles

- Cost optimization

- Quality assurance

- Market competitiveness

- Green manufacturing

DFM Advantages at Diamond Mold

Our engineers bring direct experience with international standards.

We ensure clear results with bilingual reports and seamless communication.

- Reduce potential manufacturing defects by approximately 60%

- Reduce mold manufacturing costs by approximately 15%

- Shorten the production cycle by approximately 20%

- Improve the product qualification rate by approximately 90%

Get free estimate

Bring Your Product Ideas to Life – Request Your Custom Mold & Injection Molding Quote!

FAQ

DFM (Design for Manufacturing) evaluation identifies potential manufacturing troubles in your mold design earlier than we start mold tooling. It can prevent adjustments, delays, and ensure quality and cost-efficiency.

We accept all major 3D formats (STEP, IGES, X_T, Parasolid) and 2D drawings (PDF, DWG). Please tell us your material selection, intended application and quality requirements when you send us the files.

Yes, it is for free and it is an essential step in our collaborative process.

Our report covers draft angles, wall thickness, sink marks hazard, undercuts, most efficient gate places, cooling channel layout, ejection strategy, and material suitability etc.

Absolutely. Our report includes annotated 3D images and clear, actionable suggestions for design modifications to improve manufacturability, reduce cost, and enhance quality.

The purpose of DFM (Design for Manufacturing) is to ensure smooth production, identify errors in the R&D-to-production process in advance, avoid defects caused by flawed, unreasonable, or anti-human designs during the R&D phase, reduce process losses, and improve process efficiency.

For example, consider a part as shown in the image. The mold engineer will anticipate potential flash issues that may arise during injection molding and provide reasonable suggestions. The customer adopts these suggestions, the data is modified, and mass production becomes feasible.

The earlier, the better. DFM analysis is generally required in any process involving analysis, design, and review.

The following steps should be followed when conducting DFM analysis:

1,Determine the analysis object: Select the product or component that needs to be analyzed by DFM.

2, Collect manufacturing information: Collect information related to product manufacturing, including materials, processes, equipment, etc.

3, Conduct a manufacturing feasibility assessment: Based on the collected manufacturing information, assess the manufacturability of the product and identify potential problems and difficulties.

4, Develop optimization plans: Based on the evaluation results, we will develop plans to optimize product design and improve manufacturing processes.

5, Implement optimization solutions: We can Integrate optimization solutions into the actual product design and manufacturing process.

Monitoring and Improvement: Continuously monitor the manufacturability of products during product development and production, and make continuous improvements based on feedback.

(Doesn’t it look a lot like the PDCA cycle?)

We have a dedicated project manager in your region or working hours overlapping yours. All communication is done via email and scheduled video conferences at mutually convenient times. Reports are shared on a cloud platform for 24/7 access.