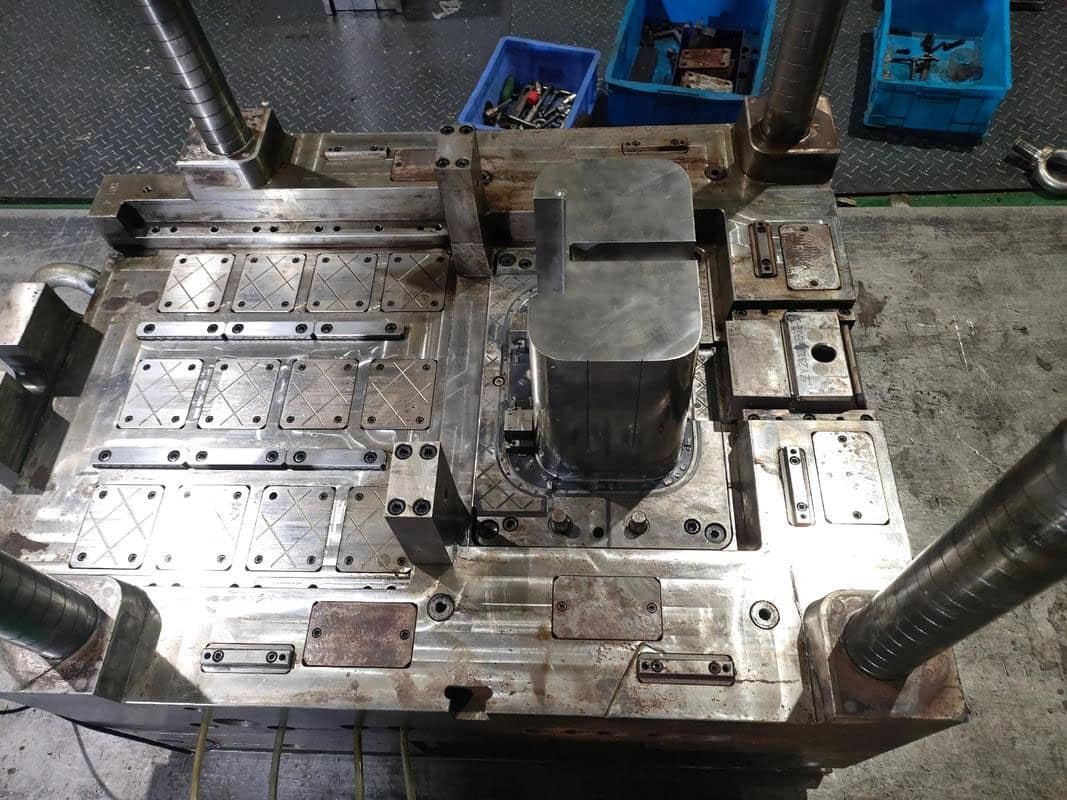

Custom Injection Mold Making Services

1, Our injection mold manufacturing process follows a strict, standardized workflow to ensure precision, stability, and consistent quality.The following outlines our typical mold-making procedure:

2, Our makers communicate and confirm the drawings designed by the mold designer. If there are no problems, the injection mold materials can be ordered. If there are any objections, the drawings need to be modified and adjusted.

3, After the injection mold material arrives, our engineer must check whether the material is qualified and meets the manufacturing requirements, and then hand it over to the mold fitter for fitter processing;

4, Our engineer performs hardness and other tests on the heat-treated workpiece to ensure there are no issues such as misalignment or scratches;

5, After heat treatment, perform electrode processing and record the data.

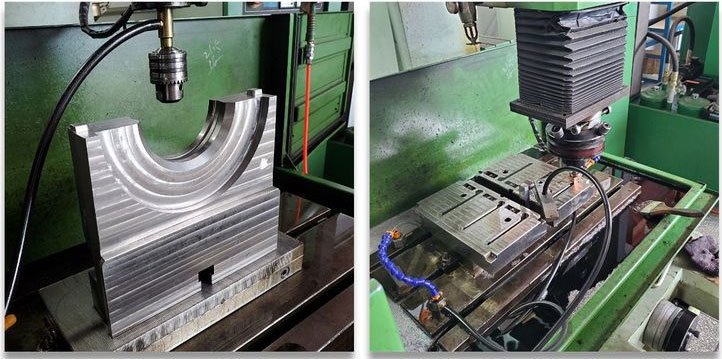

6, Wire EDM machining: Pay attention to the standards for machining each component, such as whether there is a clearance between the insert hole and the ejector pin hole;

7, For precision machining of injection molds, it is generally necessary to leave a mold-saving allowance and record the dimensions for easy inspection at any time;

8, Perform EDM processing according to the dimensions in the drawings;

9, Polish the flow channel surface to increase surface smoothness;

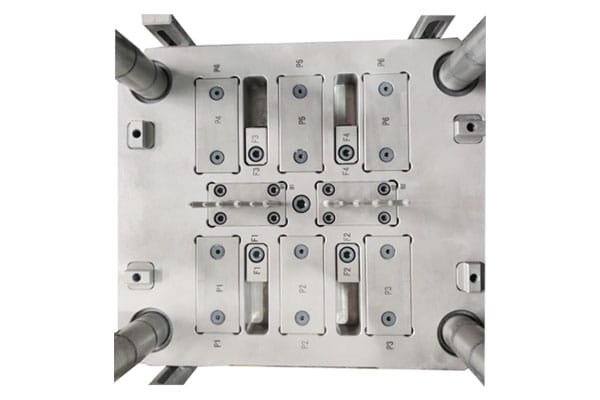

9, Inspect before assembly and perform cleaning and rust prevention treatment;

10,Injection mold assembly;

11, If trial molding and debugging were successful, and one mold was completed;

We build molds that meet the demands of complex products and high-volume production.

With advanced engineering, precise machining, and years of hands-on experience, our team is capable of delivering reliable mold solutions for a wide range of applications.

- Hot runner molds

- Two-color / multi-shot molds

- Gas-assisted molds

- High-hardness steel molds

- Unscrewing / threaded molds

- Core-pulling molds

- Overmolds

- Insert molds

- Large molds

- precision small molds

Why Choose Us

Injection mold products are diverse and complex, and the mold processes vary greatly depending on the product. Therefore, finding a manufacturer with experience in making molds for related or similar products can save you mold-making costs. Let professionals do professional work; choosing the right professional manufacturer can allow your project to quickly, accurately, and efficiently enter mass production!

Rapid mass production of molds is crucial, especially for new products where every second counts in order to quickly seize market share; time is money. Therefore, when choosing an injection mold manufacturer, it is essential to agree on a delivery date and clearly define the delivery standards for the finished products to avoid disputes.

How Diamond Mold ensure short delivery times, long lifespans, rapid mass production, and superior finished product quality for our molds?

- Analyze potential production problems based on product function, appearance, structure, and assembly, submit product analysis reports, and hold new mold meetings to ensure the product meets design requirements.

- Based on product requirements, review, analyze, and optimize the mold structure and processing technology, rationally select high-quality mold steel, and conduct full inspection at each processing step to guarantee the mold’s qualified and rapid completion.

- Optimize the distribution of the mold gating and cooling systems from a production perspective to shorten the product molding cycle and improve production efficiency and stability.

- Provide ongoing technical support to customers throughout the production process, offering mold maintenance guidelines to extend mold life.

- 20+ Years Engineering Experience

- One-Stop Mold & Molding

- Fast Turnaround & On-Time Delivery

- ISO-Certified Quality Control

FAQ

Welcome to Contact Us

If you’re looking for mold design, manufacturing solutions, or expert technical advice, our team is ready to support your project. Contact us for quick responses and professional guidance.

How long does it take to make a mold?

Usually 4–6 weeks depending on complexity.

Can you run injection molding after the mold is completed?

Yes, we offer full mold making and molding services.

Do you provide mold flow analysis?

Yes, we can provide mold flow reports upon request.

What is included in the final delivery?

Mold, design files, trial reports, spare parts, and full documentation.

How do you ensure the molds meet our national standards?

We will verify all required standards before design and follow them throughout production with material checks, dimensional inspections, and final testing.

How do you handle mold maintenance and spare parts?

We provide a maintenance guide and can supply original spare parts such as inserts, pins, and sliders. Remote technical support is also available.

What is the minimum order quantity and payment method?

There is no MOQ for molds. Payments are typically made in stages (30 deposit before manufacturing,70%final balance before). T/T and L/C are accepted.