Material And Manufacturing Characteristics Of Transparent Plastic Car Lights

February 9, 2026

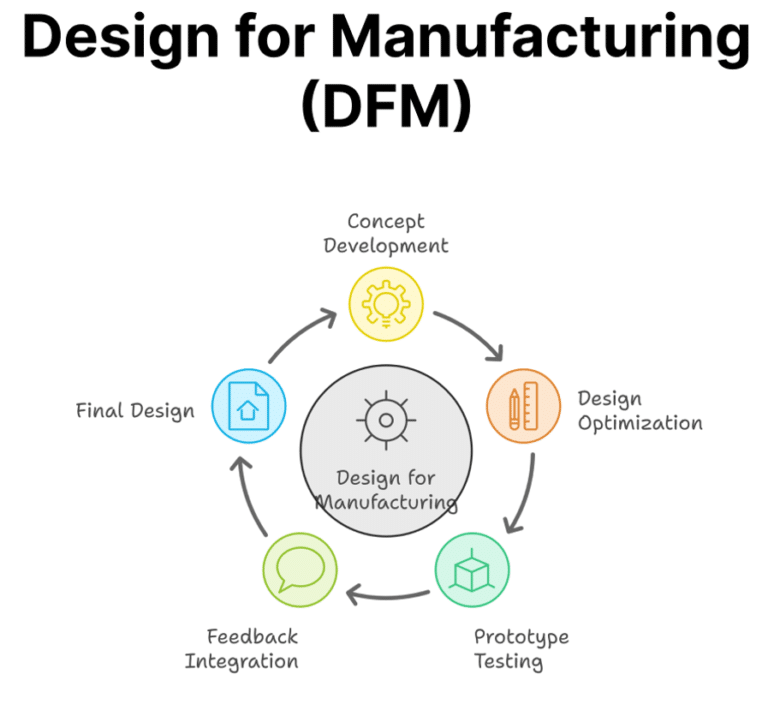

Intro The quality of automotive lighting is crucial to driving safety, hence the stringent regulations governing it in countries worldwide. Lighting design must…

Read More