What is two-shot injection molding?

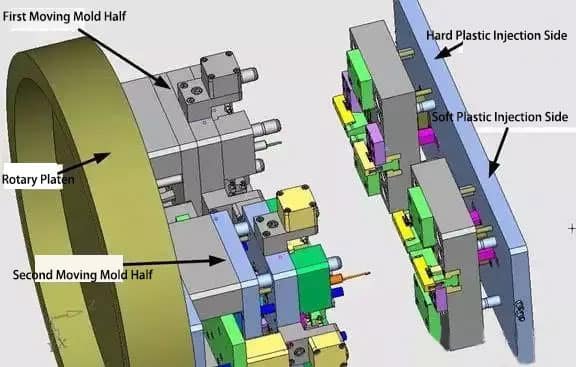

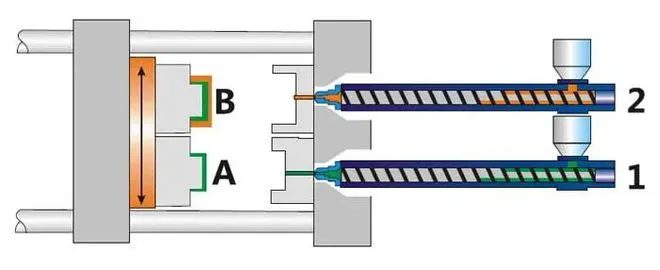

Two-shot injection molding refers to the injection molding of two plastic materials on the same injection molding machine, which is done in two stages, but the product only exits the mold once. This molding process is also generally called two-material injection molding, and it is usually completed with one set of molds and requires a dedicated two-shot injection molding machine.

Working principle of two-shot injection molding

The principle of two-color injection molding is to use an injection molding machine and two or more injection devices to alternately inject plastics of different colors or materials, so that the product can have two different colors or materials at the same time during the molding process.

What are the advantages of two-shot injection molding?

- It offers fast molding and processing with stable quality.

- It has high structural strength and excellent durability.

- It has small fitting clearances and a good appearance.

- Two-shot molds improve efficiency and reduce costs.

Material, Process, and Mold Requirements for Two-Shot Injection Molding

1, Material requirements

The mating materials for two-shot injection molding must meet two basic compatibility conditions: adhesive compatibility and processing compatibility.

2, Process requirements

Dual-shot design of soft and hard rubber

The two materials must have a certain temperature difference in melting points, generally recommended to be 60℃, and suggested to be at least 30℃ or higher. The first material has a higher melting point temperature. Generally, the first material is PC or PC/ABS, and the second material is TPU or TPE. The PC thickness is 0.6-0.7mm, and the soft material is 0.4mm or higher.

Maximize the contact area, create grooves to increase adhesion, or use core pulling for the first injection and inject part of the material into the first injection for the second injection. Make the surface of the first injection mold as rough as possible.

Transparent and non-transparent bifocal design

The dual-lens design for small lenses: the first lens is non-transparent, and the second lens is a lens. The first lens should be made of PC with a high melting point, and the second lens should be made of PMMA.

For decorative applications, a dual-shot design using both transparent and opaque materials is used: the first shot is made of opaque material, and the second shot is made of transparent material. The opaque material is often high-temperature PC, while the transparent material for the second shot is either PMMA or PC. PC requires UV coating for protection, while PMMA can be coated with UV or reinforced coatings. If there are characters on the surface, UV coating is mandatory.

3, Requirements for molds

The two shapes of the female mold must be different, each forming a different product, while the two shapes of the male mold must be exactly the same.

The front and rear molds of the mold must fit together after being rotated 180° around the center.

The maximum mold thickness, minimum mold thickness, and KO hole distance need to be carefully checked.

Ideally, the sprue of a three-plate mold should be designed to allow for automatic demolding.

When designing the master mold for the second injection molding, to prevent the secondary master mold from scratching the glued areas of the product that has already been molded in the first injection, some clearances can be designed. However, the strength of each sealing area must be carefully considered.

During injection molding, the product size of the first injection mold can be slightly larger so that it can be pressed more tightly with another mold during the second molding, thus achieving the effect of sealing.

During the second injection, be aware of whether the flow of plastic will impact the product that has already been molded the first time, causing deformation of the molded area.

Before closing the mold plates A and B, pay attention to whether the front mold slider or the angled ejector will reset first and damage the product.

The water supply arrangement of the two female molds and the male mold should be as sufficient and balanced as possible.

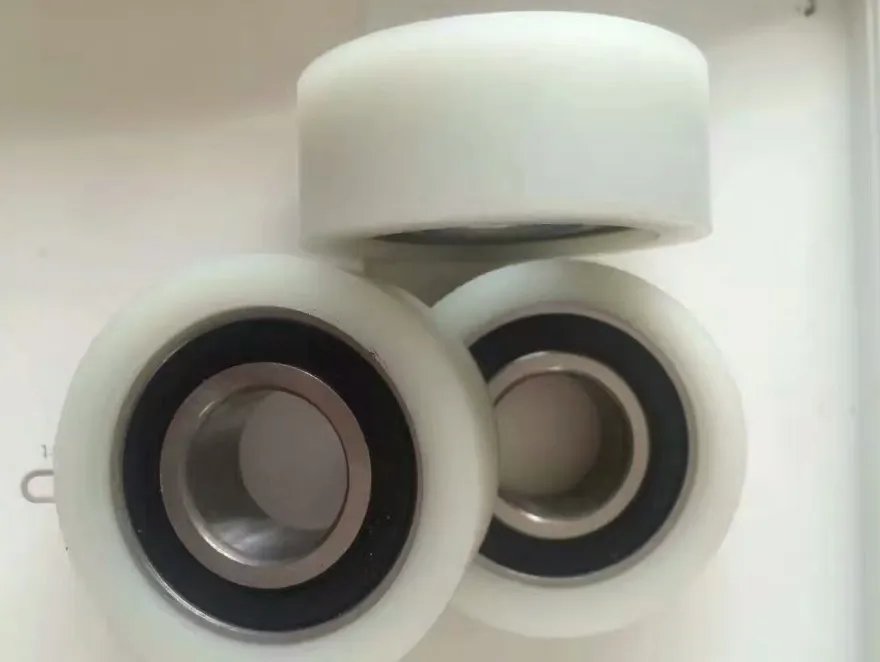

In 99% of cases, the hard plastic part of the product is injection molded first, followed by the soft plastic part, because the soft plastic part is easily deformed.

Application of dual-color molds

2K injection molding is now widely used in almost all plastic fields, including electronic products, power tools, medical products, and home appliances.